Light Fabrication

JPen (John Patrick Engineering)

The provision of both laser and plasma cutting systems provides a formidable scope of variety for both functional and aesthetic fabrication projects. Parts and sections can be quickly created following drawing approval and commitment. Using powerful and efficient technology enables the JPen to greatly reduce manufacturing times so that completed projects can be shipped out the door with minimal delay.

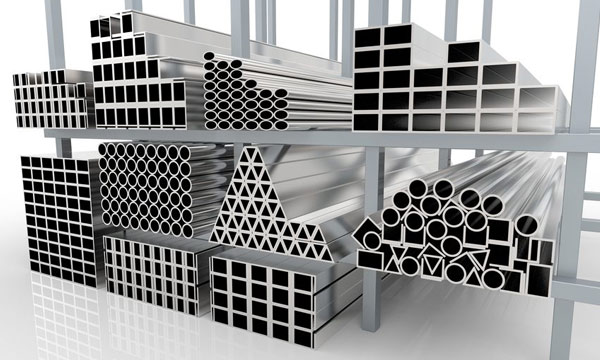

Presently projects are worked in aluminium, mild and stainless steel.

Some of the light metal fabrication projects we undertake cover a wide variety of end uses:

Steel structures for property development

Ballustrades

Gates

Aesthetic Metal Landscape Panelling

Ornate Ironwork Fencing

Bespoke storage racking and caging

Storage, racking and caging fabrications to maximise warehouse and workshop storage space usage. Clients that approach JPen often require solutions to fit their own needs and are unable to find an off the shelf mass produced product that will suffice.

Custom design loading trolleys

Tying in with storage and caging, the company is frequently tasked with producing mobile platforms, trolleys and utility vehicle beds for the transportation and loading of products that would otherwise be unsuited to regular mass produced solutions.

Workshop counters

Stainless steel work surfaces, prep areas with high quality finishes