Product Handling

JPen (John Patrick Engineering)

Custom Made Steel Fabrication for Product Handling

With well over 3 decades of experience, JPen readily produces tailor-made fabrications to suit a diverse plethora of customer requirements. Typical short lead fast output tasks include end products such as trolleys, carts, pallets, trucks, steps, ramps, storage frames and lifting equipment. Custom material handling products are essential to accessing, storing and moving other materials and products within numerous business environments. JPen has the capability to integrate its own fabricated tube, wire and sheet in order to produce high quality, durable, carefully finished mobile and static handling products.

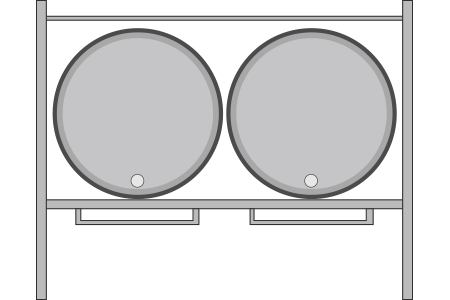

Drum Storage Units

From static rack to hydraulic pallet lifting beds, JPen regulary creates and distributes secure storage units for steel drums, compliant for the purposes of storing hazardous substances.

The storage system features sump draining capability and fluid tight welds.

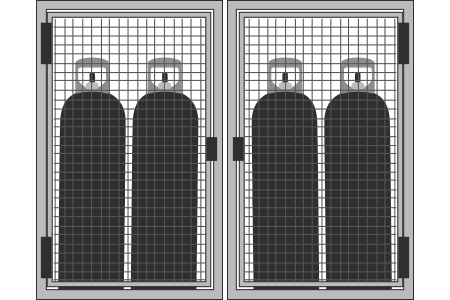

Gas Bottle Storage Cages

Storing gas bottles where good ventilation and high security is paramount, the wealth of experience in production whilst meeting strict health and safety requirements for end purpose use are primary attributes that contribute to superior grade storage products.

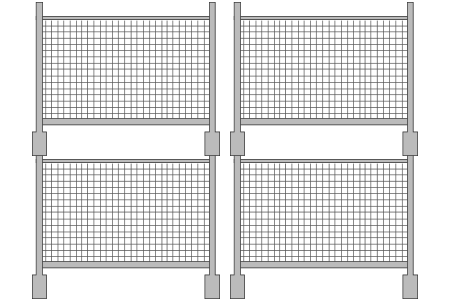

Stackable Stillages

Featuring options that allow units to be stacked 4 tiers high, steel stillage storage products are ideal for heavy and bulky items. There are options for fork lift pockets and the addition of castors to enable easier movement and lifting.

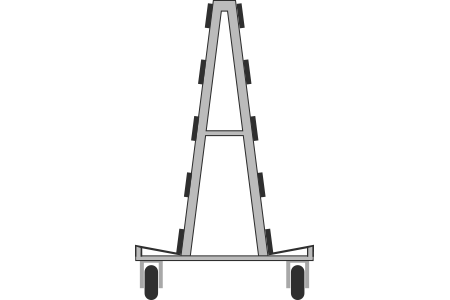

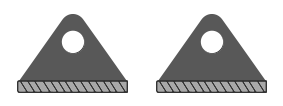

A Frame Glass Stillages

Popular demand for businesses needing to transport and store sheet glass products. A frames are inclined inwards to promote safe and secure upright stacking. Designs are carefully realised to support movement by fork lift as well as the integration of castors if required to aid in easy movement should the need arise.

Mobility, Transport and Surfacing Fittings

Lifting lugs

Hoisting lugs with load testing can be affixed (welded) to frames to suit transport requirements.

Castors

For mobility of product handling units there are a variety of load bearing, wheel or castor based systems. There are options for braking, fixed, swivel and the incorporation of truck stops.

Fork Guides

Stillages and frames can be fitted with either 2 or 4 way fork guides should prove to be a necessity. With powered lifting equipment including fork lifts and fork trolleys, our fork guides will aid in smooth and safe movement of your product handling units. There is also the option for open or enclosed fork guides.

Protection surfaces

For certain applications where additional protection is required either for transport of the product handling unit or materials loaded onto stillages, frames and baskets Jpen can supply made to fit dunnage strips and packing blocks.

Timber Panelling

Particular frame units are suited to additional surfacing that protect sheet materials in storage and transit. The most popular material in use is plywood, there are further options for aluminium, plastic and sheet steel.

Finishing

Surface treatments are available, these include:

Electroplating

Galvanising

Powder coating

Design and prototype services

JPen has a highly skilled design team with a wealth of practical knowledge and experience, the company regularly assists in the re-design of customer stillage’s to fulfil specific requirements. The benefits of our design service are:

Reduced lead time from concept to prototype.

Reduction in storage and transportation costs.

Improve overall productivity.

What Can JPen Do For You?

Time is a sparse luxury that few can enjoy within industry, JPen understands the pressure and emphasis on project completion time in conjunction with product quality first time out of the gate. If your clients depend on speed and accuracy, you can count on JPEN to support your reputation.

From small bespoke parts to large scale integrated fabrications, JPEN has the staff, skills, equipment and facilities to design, build and deploy your project.