Environmental

JPen (John Patrick Engineering)

Clay industry Exhaust Gas Scrubbers

Hellmich GmbH is a German company specialising in environmental engineering. Hellmich’s patented technology has set the standard in gas cleaning and the Fluorine Cascade Absorber (FKA) is the world market leading system for the reduction of fluorine (as hydrogen fluoride) in kiln exhaust gases.

JP Environmental – A Partnership Between JPEN and Hellmich Gmbh

JPen, through JP Environmental, has been supplying FKAs and dust extraction equipment to the UK clay industry for over 18 years. The benefits of the system are detailed further down in this article, the demand for installations of this revolutionary scrubbing facility have continued to grow as more and more customers seek to replace less efficient exhaust gas cleaning mechanisms.

JP Environmental Nationwide Claim

All the FKAs supplied by JP Environmental are fully operational to this day and continue to keep exhaust emissions below the legal limits. JP Environmental is the only supplier of such equipment that is able to make this claim.

Exhaust Gas Scrubbers

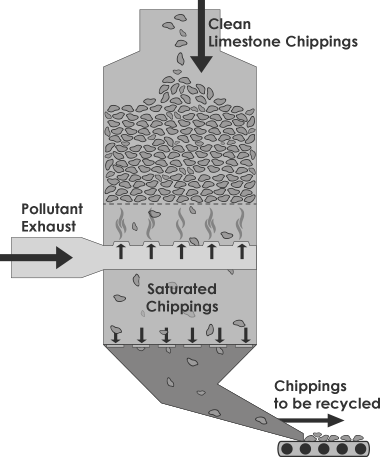

Generally speaking exhaust gas scrubbers use packed bed or packed tower scrubbers, they are designed to remove both particulate matter in addition to gaseous pollutants. The gaseous stream is fed into the exhaust venting tower system where there is a bed of special packing material. Nozzles direct a spray of scrubbing liquid that passes down through the tower onto the packing material.

As the gas passed through the packing material, the polluted exhaust gas molecules come into contact with the film of scrubbing liquid that continuously coat the scrubber packing material (usually limestone chips). The now contaminated liquid drains through the packing material, through the apertures of the packing bed and down further into the base of the tower.

The now clean gas passes through a section passed the spray nozzles and a mist eliminator before exiting the tower.

How Is The Hellmich System Different?

The Hellmich system uses a mechanism to continually remove the saturated limestone chippings into a hopper. Using a screw conveyor, the chippings are abraded using a peeling drum (rotating screen). This process ensures that the chips can then be reused for scrubbing thus creating a self-recycling process.

As an added bonus the Hellmich system does not require an absorption liquid that other gas exhaust purifiers need to coat their packing bed material. The continual cycle of the absorption chips effectively creates a dry reaction process that contributes to a lower energy demand and a much lower maintenance schedule than other existing alternatives. The Hellmich fluorine cascade absorber can also be operated using other absorption materials.

For clay manufacturing/processing companies looking to save on space and use inexpensive absorbent material that is readily available from almost anywhere, this exhaust gas scrubbing system is very hard to beat.

How Can I Enquire About A Gas Scrubbing System?

Most of JPen’s enquiries come through personal recommendations, to support this we do have an assessment team that can survey a plant for installation viability, as mentioned previously, the scrubbing system is quite the space saver, proving great worth for that reason alone. If you would like to learn more about project feasibility and costings please contact us.