Stainless And Mild Steel Stair & Staircases

JPen (John Patrick Engineering)

Stainless Steel Stairs and Staircases

Considering the end application and location of a staircase will determine what choice of steel the customer makes. Contemporary commercial staircases favour the use of highly polished stainless steel designs for their strong aesthetic appeal. Stainless steel has a high chromium content which gives that ever so obvious sheen, it is also a harder alloy than mild steel which makes it less ductile and somewhat harder to weld.

A visit to any popular consumer retail centre will almost certainly provide example of this type of staircase and or stair platforms. Stainless steel is also very popular in modern business premises, at least within the front of house areas that visitors and clients are likely to see. The landscape and hotel industry also use stainless steel stairs and balustrades to great effect, featuring a mixture of material integrated into the steel framework, such as wood, glass, laser cut panelling and even stone.

There is a greater cost for stainless steel, the price is somewhat dicated by the cost of energy used to make the alloy and secondly the skillset and time elements involved in fabrication. Mild steel is somewhat easier to work with and of course cheaper to manufacture as a raw material. That being said, stainless steel is going to pretty much outlast almost any other material in a modern building and so for that reason alone it makes a good investment choice if aesthetics and minimal to no maintenance costs are factored into the purchasing decision.

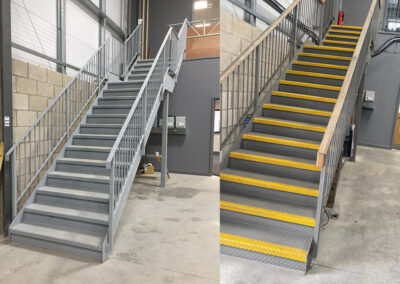

This staircase is constructed of stainless steel, painted to the customer specification; grey with yellow high visibility edge grip nosing paint and the handrails have been finished with a wooden grip/

This is an external fire escape, recently produced for a local business requiring a staircase that did not affect the building’s listed status. Purposely designed and built for a long life, minimal structural implications and a sensitive aesthetic to match the customer’s requirements while producing a safe, effective solution.

This custom-built stainless-steel staircase and platform has been painted before construction to prevent added disruption to the work place. Height of the workplace has been worked into the design, making an additional workspace on the platform.

We produce inspection and working platforms from stainless steel and carbon steel. This example gives the customer a safe and stable place to work on and inspect their product. Its safety bars help prevent falls and access points can be placed at any point along the structure making it a flexible tool in the workplace.

Mild Steel Stairs and Staircases

When budget is a prime concern and the aesthetic value doesn’t have to represent the quality of city centre hotel lobby, mild steel is certainly the choice many customers will proceed with. The most popular uses of mild steel stairs and staircases are manufacturing plants, refineries, warehouse storage premises, fire escapes and is becoming even popular in modern duel level apartments. Mild steel is much more ductile than stainless steel and so it can be formed easier into articulated shapes, grooves and bends. The cutting, forming and welding takes less time; with less hours used to complete a project and the lower cost of the raw material factored in, mild steel is a popular choice.

As mild steel does not feature the anti-corrosion properties of stainless steel, it is important to choose a method of protection for the material. Popular methods include galvanising, powder coating and traditional anti-corrosion painting. With a diverse range of colours and modern finishes available, mild steel staircases can look very impressive and so should not be relegated to just functional uses that might reside within some consumers’ perception.

What Can JPen Do With Staircases and Stairs?

The company has CE – BSEN1090 Ext3 certification meaning that the skillset and capabilities are proven and in place to be able to fabricate anything from a few stairs all the way through to staircase spanning very many floors. In any scenario, a site engineer will always make a survey and work with the project manager if required or even manage the project from start to finish if so desired by the client.